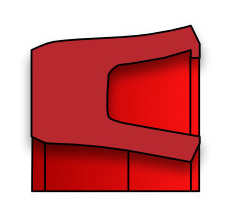

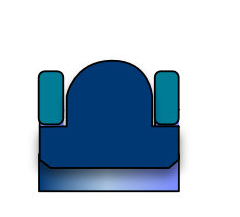

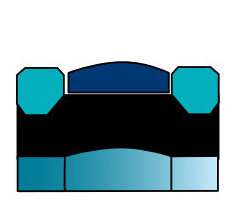

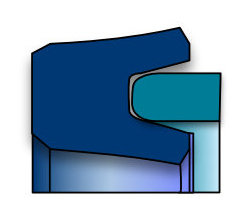

So that rolling bearings and drives, moving machine parts and dynamically stressed housings function smoothly, precisely and comprehensively -have you thought about sealing technology? If liquids and gases escape, if grease escapes, if dirt or water splashes into machinery, aggregates or equipment, functions are impaired - or worse: they cause serious damage. That is why products for reliable sealing are part of our product range for rolling bearing and drive technology. For static and dynamic sealing, we offer different designs, materials and colours.

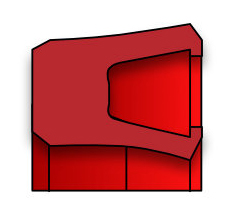

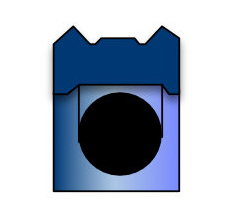

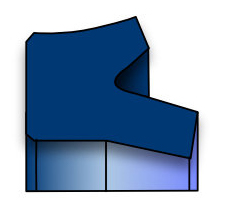

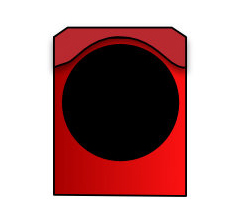

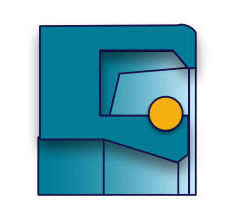

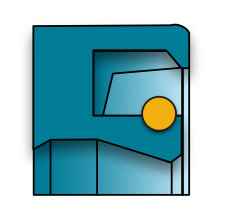

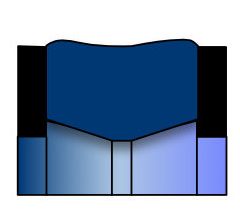

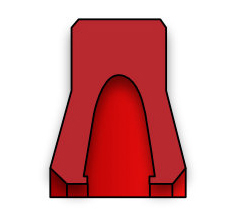

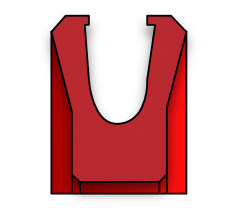

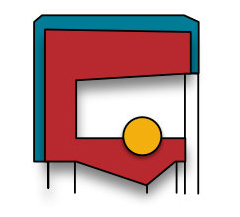

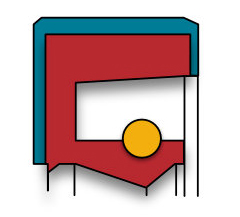

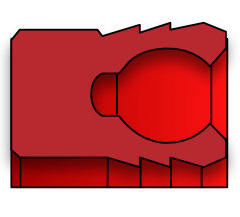

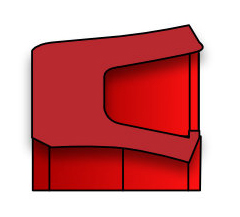

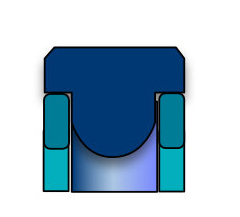

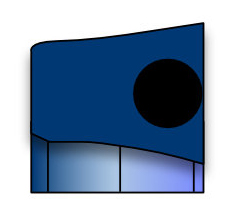

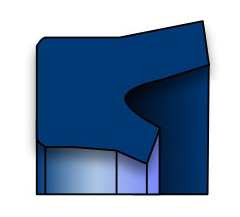

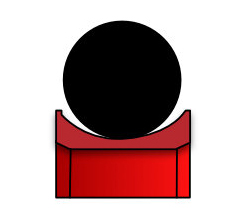

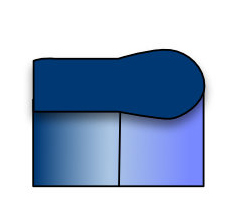

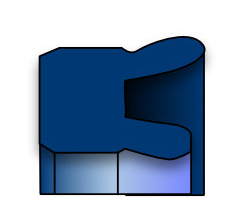

Let's keep it tight together -with O-ring, round cord, grooved ring, flat ring, support ring and cap, with X-ring, roof collar, labyrinth seal, mechanical seal, scrapers, guide elements and shaft seals.

Authorised partner of

Your contact

Mail: info[at]wagmbh.com

Tel.: +49 (0) 7543 9629 0

In addition to our standard range, special designs and special widths are also available on request.

Order online:

ONLINE-SHOP

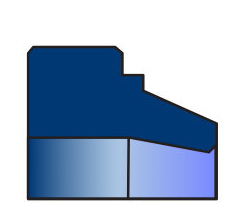

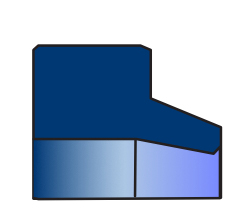

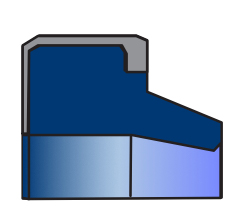

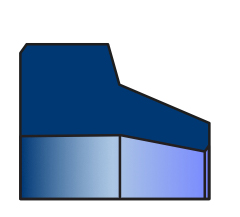

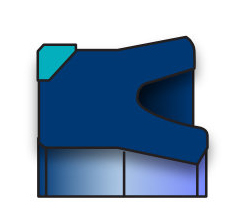

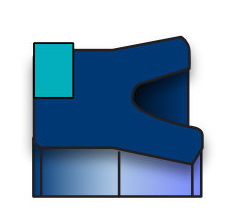

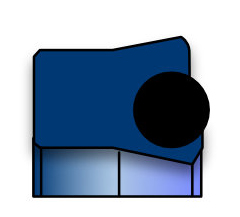

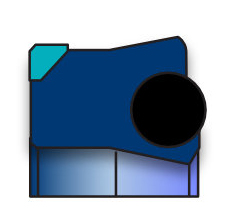

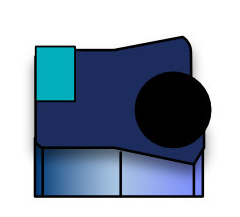

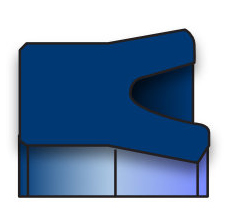

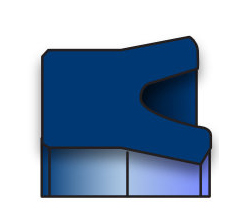

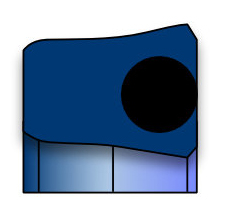

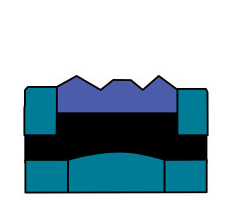

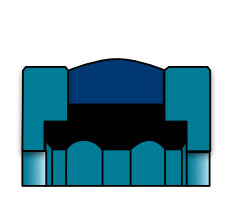

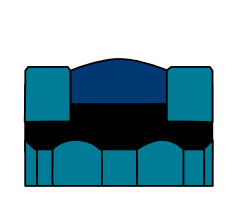

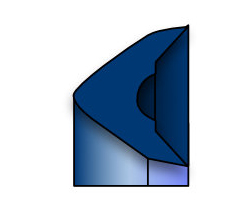

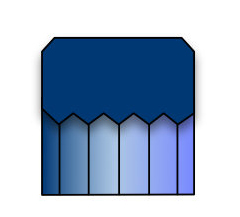

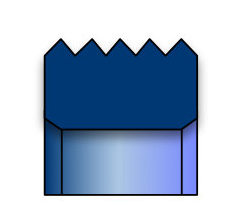

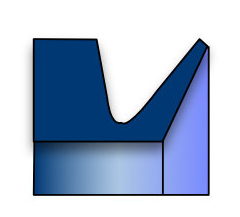

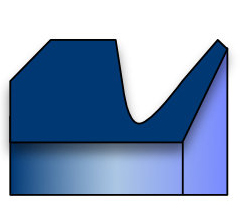

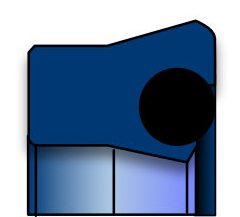

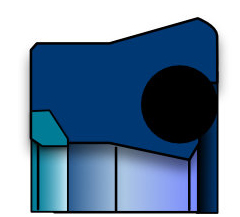

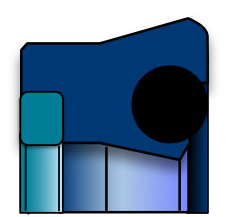

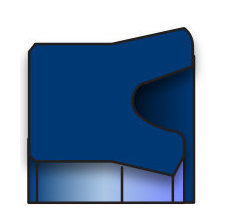

Profile overview

Selection from our standard programme

Below you will find a selection from our range of sealing technology.

Resistant to abrasive media

Version: with a PTFE impregnation or as a version with PTFE-graphite compound; diameter: 4-25 mm (or on request); square or rectangular

Structurally strong and high section density

Non-combustible

Low coefficient of friction

Design: round, square or rectangular; diameter: 3-25 mm (or on request)

Heat conductive and pressure resistant

Resistant to cold and hot water

Design: rectangular or square shape; PTFE impregnation; diameter 4-30 mm

(or on request)

Heat conductive and pressure resistant

Sensitive to UV radiation

Design: PTFE filled with graphite, core and edges are made out of arami; PTFE filled with graphite and aramid in rotation (zebra-meshwork)

High durability and absorbency

Resistant to cold and hot water, seawater, waste water, fats and oils

Design: rectangular or square, diameter 4-25 mm (or on request)

Suitable as chambering ring

Wear resistant and gentle to shafts

Very flexible and adaptable

Design: rectangular or square, diameter: 4-25 mm (or on request)

Long-term stable compression and recovery behaviour. Resistant to ageing.

water jet cutting

plotting.

Sealing materials

Depending on the application and mode of operation, different materials are used for the seals. Here is a list of the most common materials and their functions:

- HPU/PU (polyurethane) - Seals made of this material are very durable in terms of mechanical load, elasticity and gas tightness.

- NBR (acrylonitrile butadiene rubber) - Resistant to hydraulic oil and acid. Resistant to the effects of grease and petrol.

- FPM/FKM (Fluorocarbon rubber) - Resistant to mineral oils, acid, aromatic hydrocarbons.

- EPDM (ethylene propylene diene rubber) - Resistant to hot water and steam.

- Silicone - Robust against alcohols and ketones. Temperature resistant.

- PTFE (Polytetrafluoroethylene) - Temperature resistant, low wear, robust. Little elasticity.

- POM (Polyoxymethylene) - High stiffness, low friction values, very good dimensional stability.

- PA (PA6 G) - Resistant to mineral oils, acids and diluted alkalis. Used in support and guide rings.

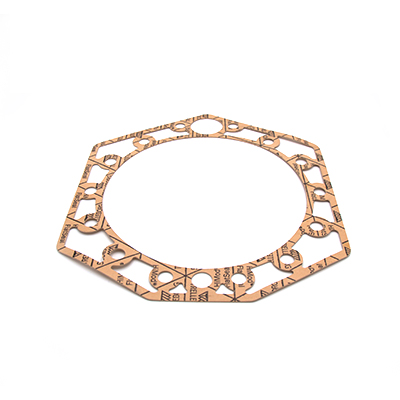

- Metal seals: In case of high or low temperatures, long service life, high radiation exposure, metal seals must be used instead of elastomer seals. In addition to the wire form, there are spring-elastic, metal-encased seals.

Materials: copper, aluminium, silver, gold, indium, stainless steel.

Sprache | Language

Sprache | Language  German

German