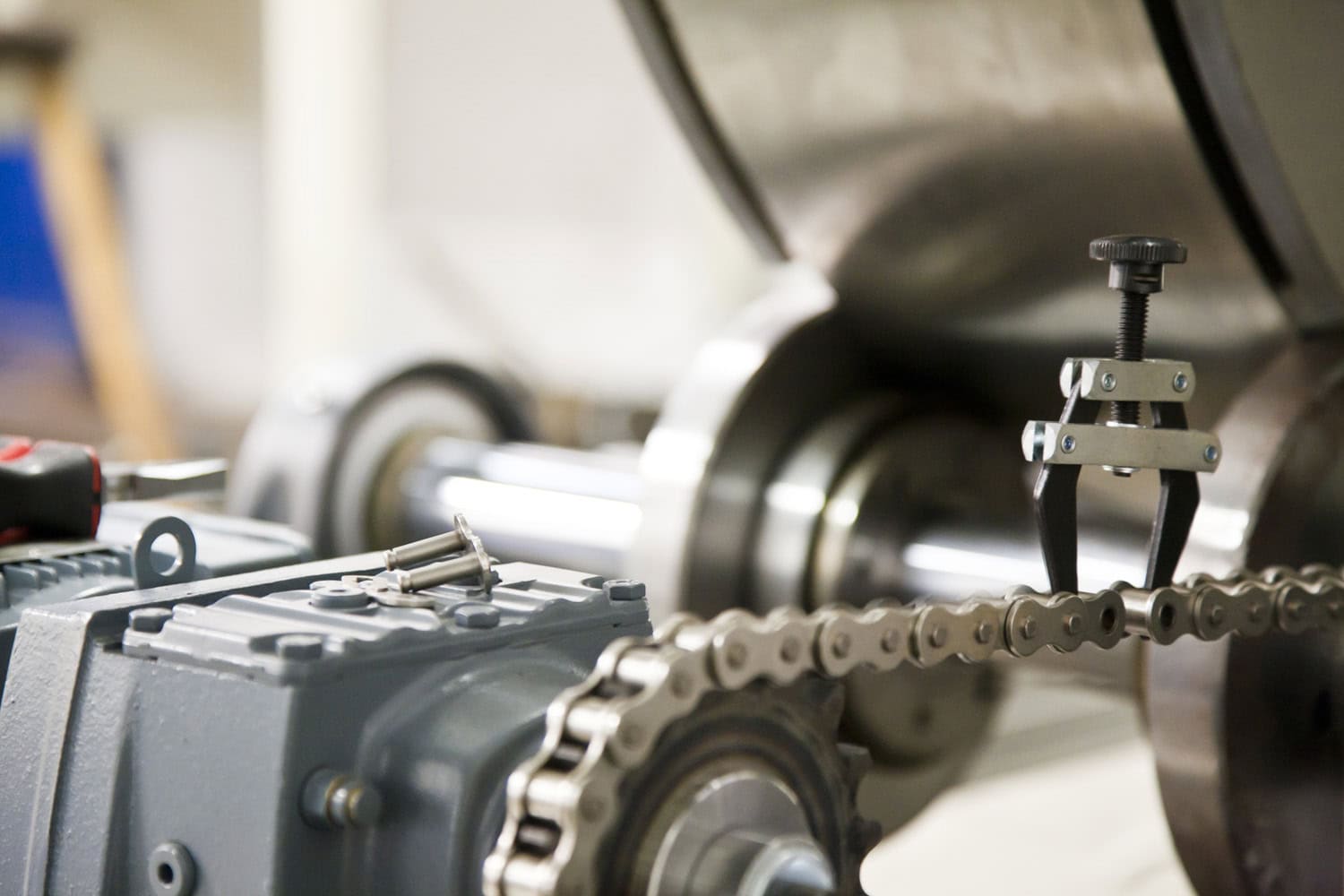

Roller chains are essential drive elements in many machines, vehicles and industrial plants. Precise measurement, correct installation and regular maintenance are crucial for their efficient and long-lasting operation. The issues of elongation, wear and lubrication play a particularly important role, as they have a significant influence on the service life and functionality of a chain.

The right measurement – what matters

Before fitting a new chain or replacing an existing one, the correct size must be determined. The pitch, inner width and pin diameter are the most important factors here. The pitch describes the distance between the centres of the pins, while the inner width indicates the space between the inner plates. Finally, the pin diameter indicates how thick the connecting elements of the chain are. An incorrect choice can lead to rapid wear or malfunctions, which is why an accurate measurement is essential.

Elongation and wear – recognise at an early stage

Roller chains stretch over time due to wear on pins and bushes. This so-called elongation means that the chain no longer engages precisely with the sprockets, resulting in uneven power transmission and increased wear. To prevent damage to the chain and sprockets, it is important to check regularly for elongation. This can be done using a special wear gauge or by simply comparing the chain with the original pitch. If the chain has become two to three per cent longer, it is high time to replace it. Otherwise, energy consumption will increase and there will be a higher load on the entire drive.

Lubrication – the key to a long service life

Correct lubrication is a decisive factor for the durability of roller chains. The use of suitable lubricants reduces friction, which significantly reduces wear. At the same time, lubrication protects against corrosion and improves the smooth running of the chain. The oil or grease should be applied specifically to the pins and plates in order to achieve an optimum effect. However, applying too thick a layer or spraying the entire chain over a large area can be counterproductive, as excess lubricant attracts dirt and deposits can form. A well-lubricated chain can extend its service life by up to 50 per cent, which is why it is worth lubricating regularly and keeping the chain clean.

Installation and regular inspection

In addition to correct measurement and lubrication, assembly also plays an important role. Before installation, you should check that the sprockets are intact, as worn sprockets cause the chain to wear out more quickly. During installation, make sure that the chain tension is neither too high nor too low. A chain that is too tight leads to excessive load and can break more quickly, while a chain that is too loose runs unevenly and can skip.

Conclusion: Care pays off

Checking your roller chains regularly, lubricating them in good time and replacing them when necessary ensures reliable and long-lasting use. Simple but consistent maintenance can prevent unnecessary breakdowns and high repair costs. A well-maintained chain is not only more efficient, but also safer in operation.

If you have any questions, please get in touch with your account manager or contact us here: